You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

700AWHP or Bust

- Thread starter BADNEWS

- Start date

underscore

Well-known member

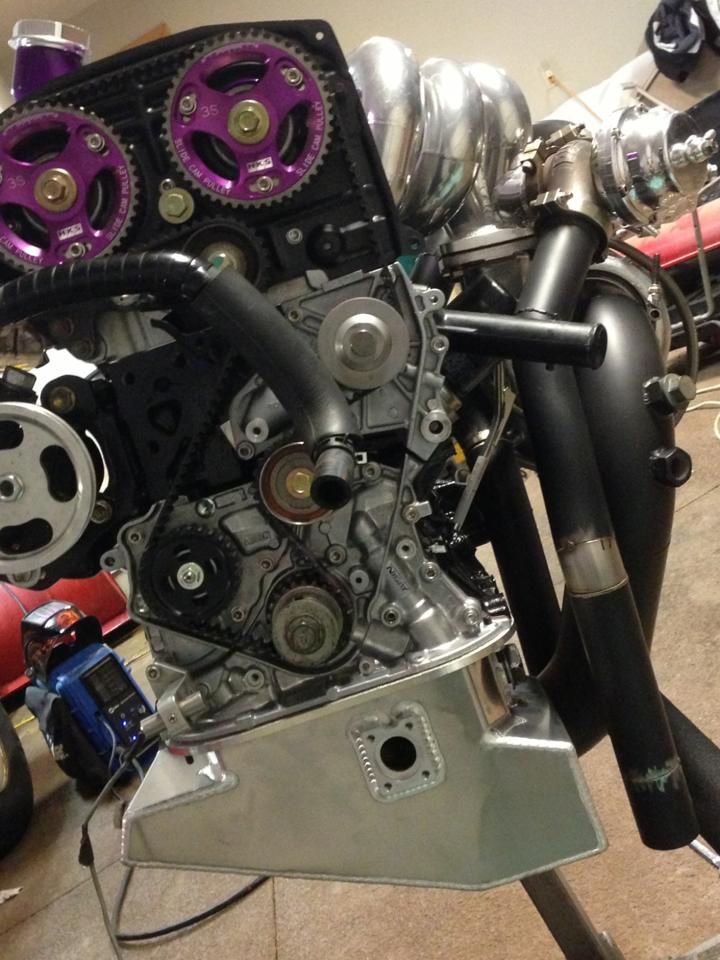

The wrinkle black gives it a very nice heavy duty look.

4rsnduction

New member

Wrinkle black looks fucking epic :notworthy:

Beautiful build RM., I can't wait to see the end result. I always love seeing the different methods/tactics guys take to make all the components of a car withstand high HP figures. I think 400 wheel will always be enough for me, if I ever get bit by the high HP bug Ill just have to go to a meet where one of you guys are and pay you for a ride.

gearhead313

New member

rm2932":3e7ggx1z said:Cause I have already cracked a 5S crank. Didn't want to go nuts on it with a knife edge to have it crack again. if I crack another one I will be getting a Brian Crower Billet Crank.

why would you not put a good crank in it then? odd..

also did you put the diff in with different bearings on old races? if so thats not quite good and will fail prematurely. just push some new bearings on it man!

BADNEWS

Member

The crank only showed after I cracked my block in a mag. I posted on the MR2 board and only one other guy has cracked his crank that I know of. So I was thinking it's more of a freak thing than anything. And I got this crank I am using for free. I didn't put the cracked crank back in. If I did switch to the BC billet that is the cost of the crank and a new set of custom rods again. His crank uses the 3S rod journal size while my rods are for the bigger 5S rod journal. That is like a $3000 swing vs a free crank. Like I said, me and an all motor 5S are the only 2 I know of to crack one. seems like a freak thing more than a problem.

I put brand new bearings on it. Selling my old diff with the 2,000 mile old bearings and races. Labeled the old ones Driver and Passenger side too for the buyer when I find one.

You can see the line in the under cut at the top of the journal going horizontal:

I put brand new bearings on it. Selling my old diff with the 2,000 mile old bearings and races. Labeled the old ones Driver and Passenger side too for the buyer when I find one.

You can see the line in the under cut at the top of the journal going horizontal:

I know a few who have cracked or warped the 5S crank. Its because the rod ratio is not ideal...

The stroker crank just doesnt seem to enjoy over 8000 rpm... which is why alot of the high HP guys are switching to an oversquare 2.1L with a 3S crank, 88mm bore in a 5S block. Much stouter.

I believe most of the 800+ guys (mostly MR2s albeit) arent running typical off the shelf bottom ends, they tend to use custom measured rods and pistons to meet their demands. Most are in favor of a piston design with shorter skirts, pin height, and longer rods to reduce side loading.

The stroker crank just doesnt seem to enjoy over 8000 rpm... which is why alot of the high HP guys are switching to an oversquare 2.1L with a 3S crank, 88mm bore in a 5S block. Much stouter.

I believe most of the 800+ guys (mostly MR2s albeit) arent running typical off the shelf bottom ends, they tend to use custom measured rods and pistons to meet their demands. Most are in favor of a piston design with shorter skirts, pin height, and longer rods to reduce side loading.

BADNEWS

Member

Checked out the rear end today. Everything was within spec. Backlash was at .005-.006, bearing preload was at about 13in/lbs, and the teeth contact looks good. So I disassembled it all now and it's getting sand blasted tomorrow. Hopefully it'll be done with the power coating by Monday.

Checking Backlash:

Checking Bearing Preload:

Coated the teeth to check contact:

Contact results look good:

Checking Backlash:

Checking Bearing Preload:

Coated the teeth to check contact:

Contact results look good:

BADNEWS

Member

CSAlltrac":1aclqfiy said:Beautiful build RM., I can't wait to see the end result. I always love seeing the different methods/tactics guys take to make all the components of a car withstand high HP figures. I think 400 wheel will always be enough for me, if I ever get bit by the high HP bug Ill just have to go to a meet where one of you guys are and pay you for a ride.

Forget a ride. I'll let you drive it. No charge either.

BADNEWS

Member

l0ch0w":3tzk5hya said:I know a few who have cracked or warped the 5S crank. Its because the rod ratio is not ideal...

The stroker crank just doesnt seem to enjoy over 8000 rpm... which is why alot of the high HP guys are switching to an oversquare 2.1L with a 3S crank, 88mm bore in a 5S block. Much stouter.

I believe most of the 800+ guys (mostly MR2s albeit) arent running typical off the shelf bottom ends, they tend to use custom measured rods and pistons to meet their demands. Most are in favor of a piston design with shorter skirts, pin height, and longer rods to reduce side loading.

So the 5S is a 91mm stroke with a 138mm rod. Giving it a rod ratio of 1.516. The 3s stock is 138mm rod with a 86mm stroke. Giving it a rod ratio of 1.605.

My engine is 142mm rod with 91mm stroke. Rod ratio of 1.560.

If I stayed with the 3s 86mm stroke my rod length. The rod ratio would be 1.651

Now if I could add half the 5mm stroke to the rod also giving me a 144.5mm rod with the 86mm stroke the rod ratio would be 1.680

What rod length do most 2.1 liter guys run?

Really, most dont bother trying to build custom piston/rod sets because running a de-stroked 3s crank in a 5s block is more than enough for their power demands and the customization costs alot of money. Hell 700WHP has been made on shot peened Stock 3s rods and crank. On top of that 5S cranks have been bent under lower HP than that. MR2Josh's original 5sgte build running a 6262 warped his 5S crank and block running e85 at only 650whp. Given e85's propensity for not knocking, and knowing his tuner, it wasnt knock that killed that crankshaft... it was 8500 RPM on a crank with a 1.5 something rod ratio... If low end is what you are looking for then a 2.3L is great, but 700+ requires some substantial RPMs which arent well suited to the 5s crankshaft. Frankly at those power levels you really don't gain that much from having the extra .2 L of displacement. Thats not to say you cant do it on a 5s crank, Its just more risky. It does help you are running a long rod with your 5S crank, but seeing as you have cracked one crank, id be all over destroking it if It were me in the hotseat.

To quote Pat:

To answer your original question, most run a 138mm rod with an 88mm bore and an 86mm stroke because its simple that way.

To quote Pat:

alltrac101":zktlx2ze said:was 870 @ 43 falling to 39.....good catch....that was with a 2.2....this is with a 2.1, my spare, Ive always wanted to try it....& yes it makes more power de-stroked...755 & 30 psi....now run the aem boost solenoids & it holds boost

To answer your original question, most run a 138mm rod with an 88mm bore and an 86mm stroke because its simple that way.

gearhead313

New member

I'll be excited to see the outcome here...

detonation doesnt really crack cranks, it has much more to do with cylinder pressure and heat. I'm guessing that is a rod journal on the "inside, facing the main? Also a fluid damper is pretty important as well. You can balance the clutch/flywheel/crank as best you can, but it will still create harmonics that destroys motors. Sure, destroke motors are great since you have to spin a low cube engine so high to get the turbo to accelerate adequately, but unless its 11k rpm, good parts and a properly blue printed motor should hold crap tons of power. dangit, i wish i had money to build me one of these things!! :notworthy:

detonation doesnt really crack cranks, it has much more to do with cylinder pressure and heat. I'm guessing that is a rod journal on the "inside, facing the main? Also a fluid damper is pretty important as well. You can balance the clutch/flywheel/crank as best you can, but it will still create harmonics that destroys motors. Sure, destroke motors are great since you have to spin a low cube engine so high to get the turbo to accelerate adequately, but unless its 11k rpm, good parts and a properly blue printed motor should hold crap tons of power. dangit, i wish i had money to build me one of these things!! :notworthy:

BADNEWS

Member

Got my rear diff all assembled after power coating the housing. Recheck everything, and it's all to spec. Got my wastegate tubes redone so they work with the new Moroso oil pan. And lastly received my uprated viscous coupling unit from Mario today. Now time to install it and get my transfer case all back together this week.